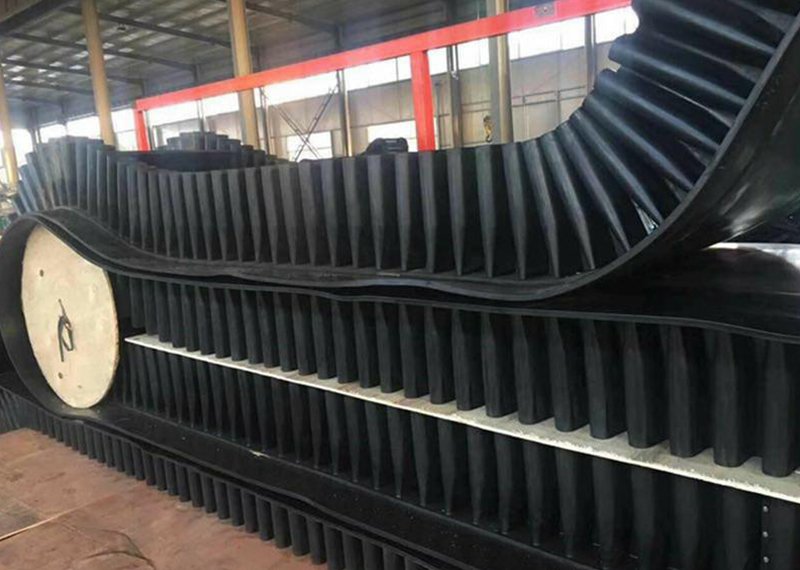

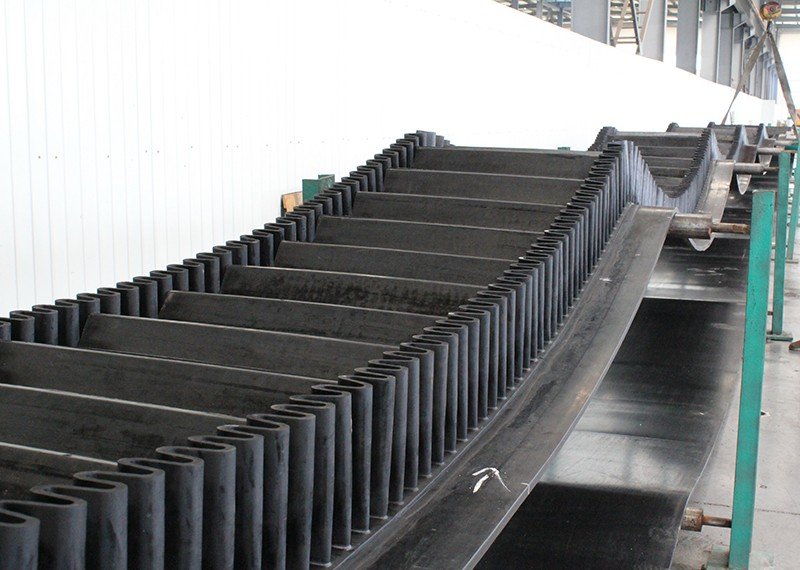

Corrugated sidewall conveyor belting is composed of three parts including base band, retaining band and diaphragm. The guard edge is used to prevent material from slipping and falling. For the convenience of bypassing the drum, the edge of the file is designed to be corrugated. The role of diaphragm is to support the material, in order to achieve large Angle conveying, using T TC type. The baffle and diaphragm are connected to the base band by a secondary vulcanization method with high bonding strength.

Corrugated sidewall conveyor belting is composed of three parts including base band, retaining band and diaphragm. The guard edge is used to prevent material from slipping and falling. For the convenience of bypassing the drum, the edge of the file is designed to be corrugated. The role of diaphragm is to support the material, in order to achieve large Angle conveying, using T TC type. The baffle and diaphragm are connected to the base band by a secondary vulcanization method with high bonding strength.

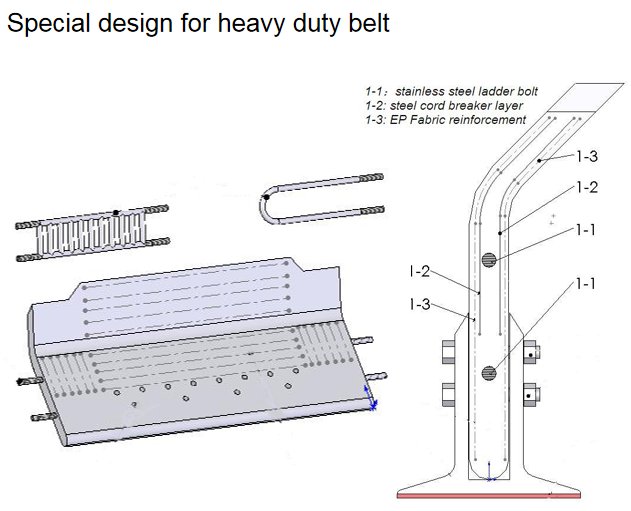

Depending on customers’ request, our sidewalls and cleats can be reinforced with diagonal fabric and bolted together. We normally use XE-layer reinforcement; However metal breaker with cross rigid character can also be applied in various specifications. We offer a?large portfolio of possible combinations of cleats and sidewalls in height up to 500mm.

Applications

This belting can be used for conveying bulk materials with a dip Angle of 0° ~ 90°. It solves the conveying Angle that the pattern belting and ordinary flat belting cannot reach, increases the lifting height, and has the advantages of shortening the transportation distance of the conveyor, reducing the cost and saving manpower and material resources.

Waveform sidewall rubber conveyor belting can now cover all industries, whether mining, chemical, building materials, metallurgy, steel and other industries have its figure. Its existence can be said to provide convenience for transportation, to solve a series of problems such as high cost of large , easy to spread materials, can not be completely vertical transportation. sidewall rubber conveyor belting can be completely realized, and a conveyor belting can realize multiple Angle conversion. Like 30 degrees on the bottom, 90 degrees on the top.

Advantages

Corrugated sidewall conveyor beltings has the following advantages:

Save space, it does not need to occupy too much place is not very big , but occupies less area, because it is the Angle of transport.

Do not occupy too much capital, small investment, less cost, the production of high economic benefits!

Easy installation, simple maintenance, made into a ring is very convenient to install, go back directly with the crane can be lifted!

Usually only regular inspection and maintenance, timely repair of falling guard and partition.

Base belt

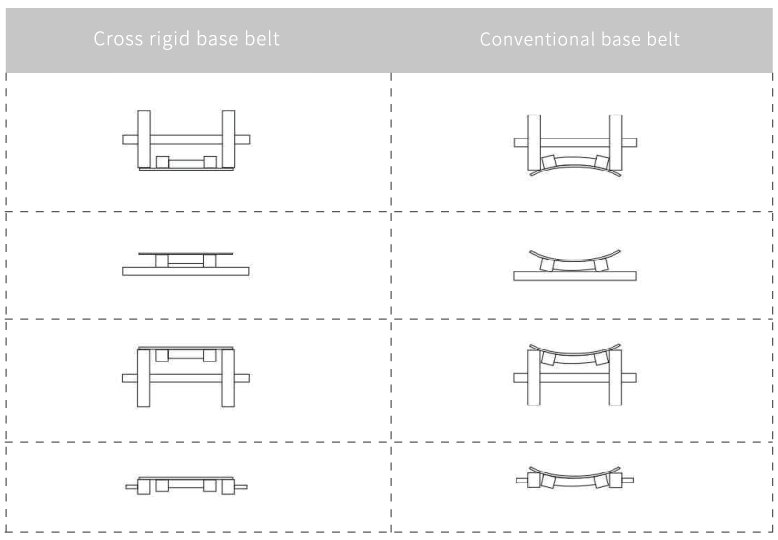

• Sidewall belts require a certain tensile strength and abrasion resistance. For belt has to have enough cross rigidity and flexibility longitudinally to meet up with the requirement of deflection part of conveyor. The special designed base belt with cross rigidity solved the problem of belt deformation. The belt standand are in accordance with international tandard.

• XE This belt incorporates the transverse polyester monofilament cords within the fabric, mainly used for small and medium sized applications.

• XE+2 The cross rigid and tensioning plies are separate,in this case the belt has 2 cross-rigid polyester monofilament plies, application areas are medium to heavy.

• XE-SC+2 This belt incorporates textile tensioning plies with closely pitched and specially designed steel cords. The high lateral stiffness means the belt can be used in application areas where rigidity is an important factor, i.e. High lift heights and wide belts.

| TYPE | Model | Tensile | Cover | Weight | Min.Pulley |

| Strength | Thickness | (Kg/M) | Diameter | ||

| (N/Mm) | (Mm) | (Mm) | |||

| XE |  | 250/2 | 2:2 | 9.4 | 200 |

| 400/3 | 4:2 | 13.5 | 315 | ||

| XE+2 |  | 400/3+2 | 4:2 | 12.1 | 315 |

| 500/3+2 | 4:2 | 12.6 | 400 | ||

| 630/3+2 | 4:2 | 14.4 | 500 | ||

| 800/5+2 | 4:2 | 16.1 | 630 | ||

| 1000/5+2 | 4:2 | 17.8 | 800 | ||

| 1250/5+2 | 4:2 | 18.25 | 1000 | ||

| XE-SC+2 |  | 315/2+2 | 4:2 | 13.7 | 315 |

| 400/3+2 | 4:2 | 14.8 | 315 | ||

| 500/3+2 | 4:2 | 15.2 | 400 | ||

| 630/4+2 | 4:2 | 16.7 | 500 | ||

| 800/5+2 | 4:2 | 18.0 | 630 | ||

| 1000/5+2 | 4:2 | 19.5 | 800 | ||

| 1250/5+2 | 4:2 | 21.4 | 1000 | ||

| XST-SC* |  | 1600 | 8:8 | PLEASE INQUIRE | 1250 |

| 2000 | 8:8 | 1250 | |||

| 2500 | 8:8 | 1400 | |||

| 3150 | 8:8 | 1400 | |||

| 3500 | 8:8 | 1600 | |||

| 4500 | 8:8 | 1600 | |||

| 5000 | 8:8 | 1600 | |||

| 5400 | 8:8 | 1800 | |||

| 6000 | 8:8 | 1800 |

Rubber quality

• Black Standard High Abrasion Resistant

• Moderate Oil Resistant.

• Heat Resistant to 150℃

• High Heat Resistant to 180℃

• Flame Retardant

• Other qualities may be available to special order, please enquire.

Sidewall

Rubber qualities

• Black Standard High Abrasion Resistant

• Moderate Oil Resistant.

• Heat Resistant to 150℃

• High Heat Resistant to 180℃

• Flame Retardant

• Other qualities may be available to special order, please enquire.

Fabric reinforcement

FRONT sidewalls from type S120/MDSF120 and higher have special diagonal fabric reinforcement in the corrugations as standard, smaller sidewalls can have this feature if required.

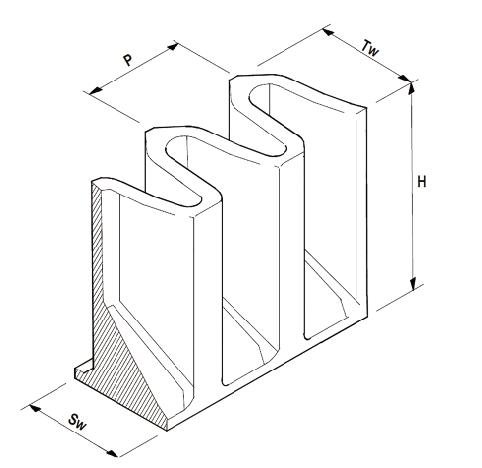

| Type | Sw(mm) | Tw(mm) | P(mm) | EST Weight(kg/m) |

| S | 30 | 20 | 25 | 0.45 |

| 50 | 45 | 40 | 1.38 | |

| 50 | 45 | 40 | 1.70 | |

| 50 | 45 | 40 | 2.00 | |

| 50 | 45 | 40 | 2.65 | |

| MDSF | 75 | 65 | 63.5 | 3.20 |

| 75 | 65 | 63.5 | 4.20 | |

| 75 | 65 | 63.5 | 5.02 | |

| 75 | 65 | 63.5 | 7.50 | |

| 75 | 65 | 63.5 | 7.80 | |

| 75 | 65 | 63.5 | 8.70 | |

| 75 | 65 | 63.5 | 9.40 | |

| HHDF | 100 | 90 | 83 | 10.10 |

| 100 | 90 | 83 | 14.80 | |

| 105 | 95 | 89 | 19.10 |

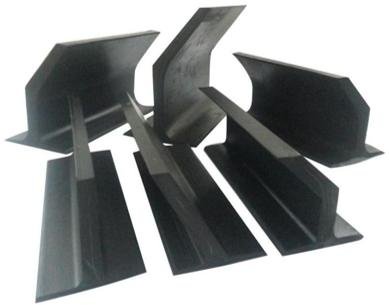

Cleat

Front cleats have been specifically design to give optimum performance.

The shape of the ‘C’ and ‘TC’ types has been created to offer the best conveying capacities along with excellent self-cleaning properties.

Front cleats are molded with features of strong stiffness abrassion resistant and impact resistance to give the best shape retention even when conveying high-density materials.

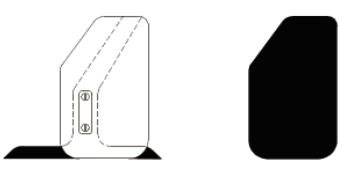

Side blinkers

Side blinkers can be fitted in-between the cross cleats,profile and the sidewall to make a seal. Side blinkers are used when the material is particularly free flowing.

| cleat type | application | Features | ||||||

| T | Conveying angle ≤40 deg. | |||||||

| C | 40 deg.<Conveying angle ≤ 90 deg. Light duty | Small capacity, excellent self-cleaning properties, no screw reinforcement with sidewall. | ||||||

| TC | 40 deg.<Conveying angle ≤ 90 deg. | Capacity big,excellent self-cleaning properties. | ||||||

| TX-XS | 40 deg.<Conveying angle ≤ 90 deg. Heavy duty | Capacity big,replaceable cleat blade. | ||||||

| Cleat type | Height(mm) | Base width (mm) | EST Weight (kg/m) | Min pulley dia (mm) |

| 55 | 100 | 1-45 | 125 |

| 75 | 100 | 2.00 | 150 | |

| 90 | 110 | 2.81 | 250 | |

110 | 110 | 3.27 | 315 | |

| 55 | 100 | 1-61 | 125 |

| 75 | 100 | 2.20 | 150 | |

| 90 | 110 | 2.70 | 250 | |

| 110 | 110 | 3.23 | 315 | |

| 140 | 160 | 5.49 | 400 | |

| 180 | 160 | 6.67 | 500 | |

| 230 | 160 | 8-60 | 630 | |

| 55 | 75 | 1.13 | 125 |

| 75 | 100 | 1.82 | 150 | |

| 90 | 110 | 3.22 | 250 | |

| 110 | 110 | 3.94 | 315 | |

| 140 | 150 | 5.49 | 400 | |

| 180 | 150 | 6.81 | 500 | |

| 230 | 160 | 8.68 | 630 | |

| 280 | 180 | 14.90 | 800 | |

| 230 | 160 | 13.80 | 630 |

280 | 160 | 15.30 | 800 | |

360 | 230 | 22.80 | 1000 | |

470 | 230 | 30.80 | 1250 |

Please fill out the form below and we will get back to you as soon as possible.